ASIAGO DOP FRESCO

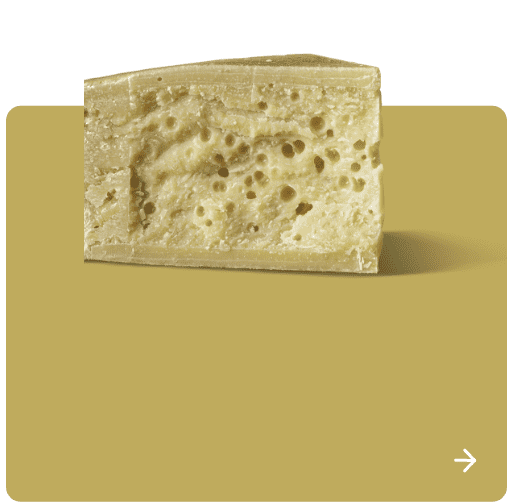

ASIAGO DOP Stagionato

DA 20 GIORNI

- Asiago DOP

- Fresco

- Fresco

ASIAGO DOP FRESCO

ASIAGO DOP Stagionato

ASIAGO DOP FRESCO

ASIAGO DOP Stagionato

ASIAGO DOP FRESCO

ASIAGO DOP Stagionato

ASIAGO DOP FRESCO

ASIAGO DOP Stagionato

ASIAGO DOP FRESCO

ASIAGO DOP Stagionato

Positività, ottimismo, condivisione. Con il brano musicale “See far” Asiago DOP celebra un nuovo presente, quello che scorre a tempo di sì.

Scopri di più

Scopri di più

Scopri di più

Scopri di più

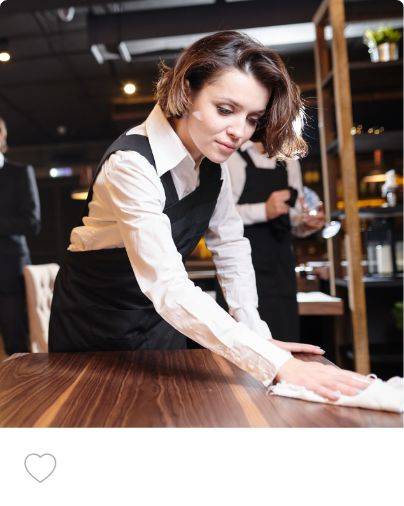

Per il mondo della ristorazione, ci siamo. Con tanti nuovi progetti per creare una filiera virtuosa che valorizzi le eccellenze del territorio e il piacere di gustarle.

Perché non siamo solo un ingrediente. Siamo una ricetta per ripartire, insieme.

Un territorio incontaminato dalle caratteristiche uniche al mondo, dove nasce da mille anni un prodotto senza eguali: Asiago DOP.

Caseifici, malghe e stagionatori. Tutti accomunati da una grande passione: lo straordinario formaggio di cui custodiscono la tradizione.

© Copyright 2022 ©CONSORZIO TUTELA FORMAGGIO ASIAGO| P.IVA / CF: 00703580241 | Privacy Policy | Cookie Policy